What is a Valve Interlock? A Comprehensive Guide to Mechanical Safety Systems for Industrial Valves

In the complex and high-stakes world of industrial process management, ensuring operational safety is paramount. Among the critical safety devices that prevent human error and catastrophic incidents is the Valve Interlock. This article provides an in-depth exploration of what a valve interlock is, how it functions, its various types, and why it is indispensable for industries like oil and gas, petrochemicals, and power generation. We will also highlight the expertise of Shanghai Nodango Safety Equipment Co., Ltd. (Nudango), a leading innovator in this field.

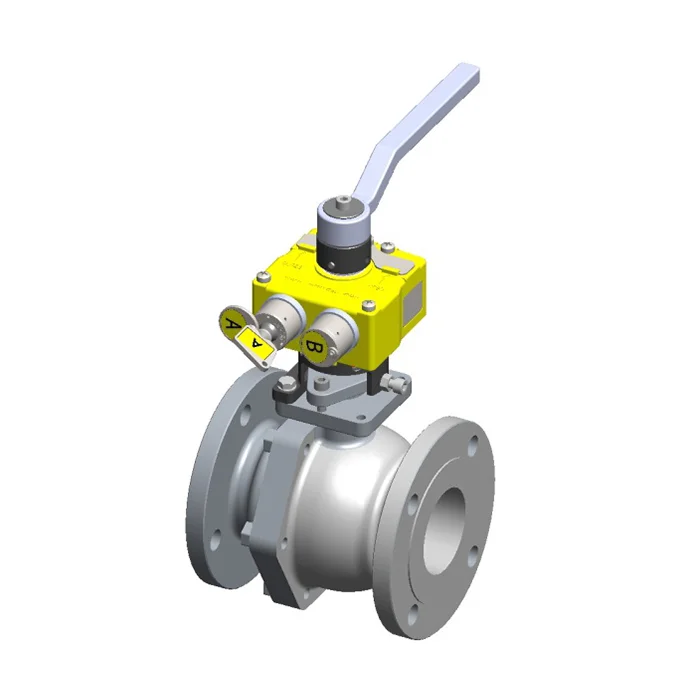

Rotary motion valve interlock (Model VJ) – A robust mechanical valve interlock system ensuring safe valve operation sequences.

Understanding the Core: What is a Valve Interlock?

A Valve Interlock is a mechanical safety interlock for valve safety management designed to enforce a predetermined sequence of operations on valves, preventing incorrect manipulation that could lead to dangerous situations like pressure releases, mixing of incompatible fluids, or equipment damage. At its heart, it is a mechanical key interlock for valves that uses a physical key exchange system to control access and operation.

Think of it as a traffic light system for your industrial pipeline. It ensures that Valve B cannot be opened until Valve A is securely closed, and the key proving this state is transferred. This simple yet powerful mechanical logic eliminates reliance on human memory or procedural adherence, providing a fail-safe layer of protection.

How Does a Mechanical Valve Interlock System Work?

The operation is elegantly straightforward, relying on physical mechanics:

- Key Trapping: A unique key is trapped in the interlock device when the valve is in a specific position (e.g., fully open or fully closed).

- Key Release & Transfer: Only when the valve reaches the correct position is the key released. This key is then the "token" required to operate the next valve in the sequence.

- Sequential Enforcement: This creates a forced sequential operation, forming a sequential valve interlock system. The system physically prevents operators from bypassing the safe procedure.

This makes it an ideal pipeline valve interlock safety device, crucial for isolation, draining, purging, and commissioning procedures.

Types of Valve Interlocks: Matching the Mechanism to the Application

Different valve types require specialized interlock designs. Here are the primary categories, areas where Nudango offers extensive customized valve interlock solutions:

1. Quarter-Turn Valve Interlock

Designed for ball valves, plug valves, and butterfly valves that require a 90-degree rotation to operate. These are common safety valve interlocking devices for quick-acting valves.

2. Multi-Turn Valve Interlock

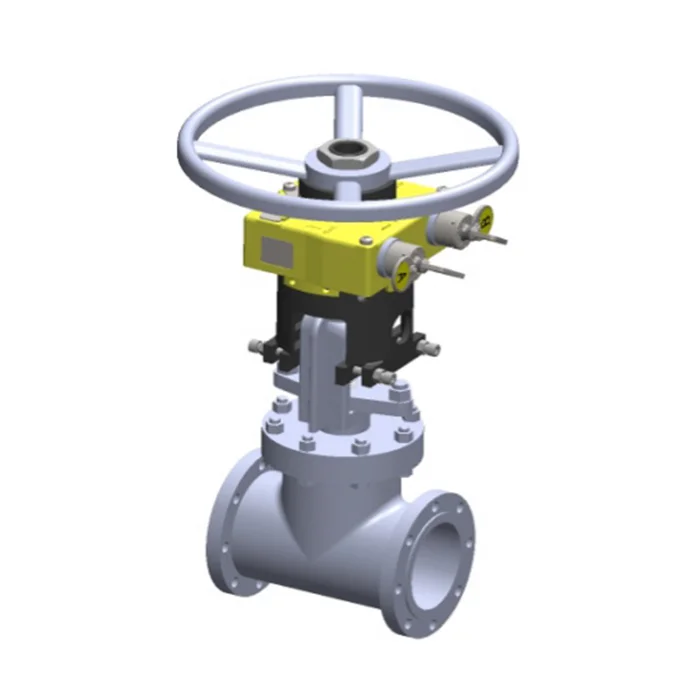

Used for gate valves, globe valves, and rising stem valves that require multiple rotations. Nudango's Multi-turn valve interlock (model VDS / VDL) is engineered for precise control and durability in demanding cycles.

3. Key-Operated Valve Interlock & Mechanical Key Interlock for Valves

This is the foundational concept. A key-operated valve interlock uses a dedicated key that is only accessible when the valve is in the correct state, providing a simple and highly reliable access control mechanism.

4. Specialized Interlocks for Complex Setups

- Drive Valve Interlock: Secures valve actuators and gear operators. Nudango's Drive Valve Interlocking system ensures that motorized or gear-driven valves cannot be engaged unsafely.

- Gear box valve interlock: Specifically designed for valves with gearboxes, adding a critical safety layer to torque-intensive operations.

- Rotary motion valve interlock: A broad category covering any valve operated by rotational force, ensuring the handle or lever is locked in position.

Why are Valve Interlocks Critical? The Industry Imperative

The need for robust industrial valve safety interlock systems is driven by safety, regulatory, and operational efficiency demands.

- Safety in Hazardous Industries: A valve interlock for oil and gas industry or a petrochemical valve interlock system prevents accidental releases of hydrocarbons or toxic chemicals, protecting personnel, assets, and the environment.

- Compliance with Safety Standards: Interlocks help plants comply with Process Safety Management (PSM) and Safety Instrumented Systems (SIS) requirements.

- Prevention of Human Error: They are the ultimate "idiot-proof" device, enforcing correct procedure regardless of operator experience or stress level.

- Asset Protection: Prevents mechanical damage to valves and pipelines from incorrect sequencing (e.g., water hammer).

Material and Design for Extreme Conditions

Industrial environments are punishing. Therefore, interlock construction is vital:

- Stainless Steel Valve Interlock: Offers excellent general corrosion resistance and strength. A common choice for many applications.

- Corrosion-Resistant Valve Interlock: Made with specialized alloys or coatings (e.g., zinc-nickel plating) for highly corrosive chemical environments.

- Explosion-Proof Valve Interlock: Designed with flame paths and robust housings to prevent ignition in hazardous areas (ATEX/IECEx zones).

- Harsh Environment Valve Interlock: Built with superior seals and materials to withstand extreme temperatures, moisture, dust, and outdoor exposure, much like the products from Nudango which are known for excellent moisture-proof, mildew-proof, rust-proof, and dust-proof properties.

Nudango: A Trusted Partner in Valve Safety Solutions

When selecting a valve interlock provider, expertise and reliability are non-negotiable. Shanghai Nodango Safety Equipment Co., Ltd. (Nudango) stands out as a professional partner dedicated to safety system engineering.

Company Strength and Innovation

Nudango is not just a manufacturer; it is a solutions provider engaged in safety planning, consulting, design, and manufacturing. With numerous patented technologies and collaborations with universities and research institutions, they drive innovation in mechanical interlock for valve safety management.

Their production capability is underscored by a modern facility, as seen in their production workshop and organized warehouse, ensuring quality and timely delivery.

Certifications and Global Reach

Quality is systemically assured. Nudango's products comply with the GB/T19001-2015 idt ISO9001:2016 quality management system standard. They hold a comprehensive set of management system certifications, including Environmental and Occupational Health & Safety (ISO 14001 & ISO 45001), and their products carry the CE mark for the European market. This commitment to international standards makes them a reliable global supplier.

Their products are exported worldwide, including to Taiwan, Vietnam, India, Saudi Arabia, Brazil, Germany, and more, proving their acceptance in diverse valve interlock for oil and gas industry and other critical sectors.

Complete Product Portfolio and Support

Beyond standard interlocks, Nudango's portfolio includes advanced systems like the SCU (Sequential Control Unit) for complex multi-valve sequences, and the Limit interlock XWIL. They provide end-to-end support from design to after-sales service.

Contact Nudango for Your Valve Safety Needs

For customized valve interlock solutions that enhance your plant's safety and efficiency, reach out to the experts.

Company: Shanghai Nodango Safety Equipment Co., Ltd. (Nudango)

Phone: +86 13052019523

WhatsApp: +86 13816485040

Email: globalnudango@shndg.cn

Website: https://www.nudango.com/

Address: No.124, Block C, No.1118 Guchen Road, Baoshan District, Shanghai, P.R.C.

Conclusion

A Valve Interlock is far more than a simple lock; it is an intelligent, mechanical guardian of process integrity and personnel safety. Understanding the different types—from quarter-turn and multi-turn valve interlocks to specialized drive and gear box valve interlocks—is the first step in implementing an effective safety strategy. For industries operating under high pressure, both literally and figuratively, partnering with a certified and innovative provider like Nudango ensures access to reliable, durable, and compliant mechanical valve interlock systems that stand the test of time and harsh conditions.