How to Select the Right Valve Interlock System for Your Industrial Application

In the complex and often hazardous world of industrial operations, ensuring process safety is non-negotiable. A valve interlock system stands as a critical line of defense, preventing human error and enforcing safe operating sequences. However, with various types like mechanical valve interlock systems, quarter-turn valve interlocks, and multi-turn valve interlocks available, selecting the right one can be daunting. This guide, brought to you by Shanghai Nodango Safety Equipment Co., Ltd. (Nudango), will walk you through the key considerations to make an informed, safe, and cost-effective choice for your facility.

Understanding the Core Purpose: Why Valve Interlocks are Non-Negotiable

Before diving into selection criteria, it's crucial to understand the role of a safety valve interlocking device. These are physical mechanisms that control access to valves through a system of keys. They enforce a predetermined sequence of operations, ensuring that valves are opened or closed in the correct order. This prevents dangerous scenarios such as backflow, over-pressurization, mixing of incompatible media, or unintended energy release. In industries like oil & gas, petrochemicals, and power generation, the correct application of a valve interlock for oil and gas industry or a petrochemical valve interlock system is often mandated by safety standards and is a cornerstone of Process Safety Management (PSM).

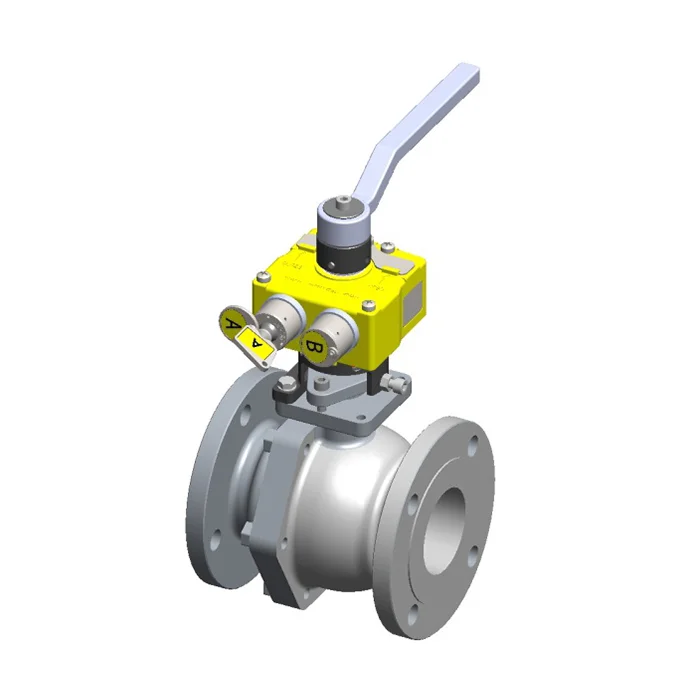

Figure 1: Nudango's VJ model is a robust rotary motion valve interlock designed for quarter-turn valves like ball and plug valves, commonly used in pipeline safety.

Step-by-Step Selection Guide

Step 1: Identify Your Valve Type and Motion

This is the most fundamental step. The valve's operation dictates the interlock type.

- Quarter-Turn Valve Interlock: Designed for valves that require a 90-degree rotation to open or close (e.g., ball valves, plug valves, butterfly valves). Nudango's specialized models for these are compact and highly reliable.

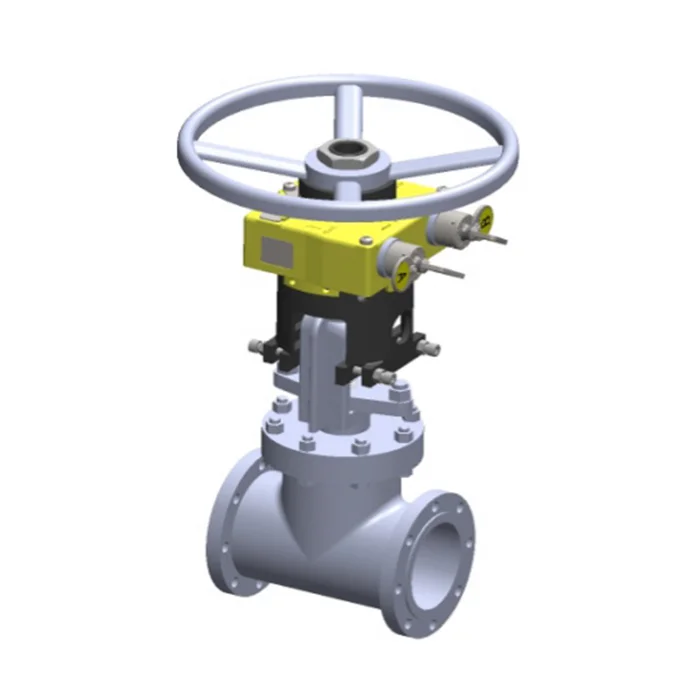

- Multi-Turn Valve Interlock: Used for valves requiring multiple rotations (e.g., gate valves, globe valves, rising stem valves). These systems, like Nudango's VDS/VDL models, are built to handle linear or combined rotary-linear motion securely.

- Drive Valve Interlock / Gear Box Valve Interlock: Essential for motor-operated valves (MOVs) or valves with gear operators. These interlocks, such as Nudango's dedicated solutions, lock the handwheel or drive mechanism, preventing unauthorized or incorrect actuation of powered systems.

Figure 2: Nudango's VDS/VDL series multi-turn valve interlock ensures safe operation of gate and globe valves, integral to industrial valve safety interlock protocols.

Step 2: Assess the Operational Environment

The operating conditions severely impact material choice and design.

- Corrosive & Harsh Environments: Offshore platforms, chemical plants, and wastewater facilities demand corrosion-resistant valve interlocks. Stainless steel valve interlock (e.g., 304 or 316 SS) is the standard choice from Nudango for excellent resistance.

- Explosive Atmospheres (ATEX/IECEx Zones): In the oil and gas industry, areas with flammable gases or dust require explosion-proof valve interlock designs that prevent sparking.

- Extreme Temperatures & Weather: For outdoor or furnace applications, ensure the interlock materials can withstand the temperature range without losing mechanical integrity.

Nudango's products are engineered for harsh environment valve interlock use, featuring excellent moisture-proof, mildew-proof, and rust-proof properties.

Step 3: Define Your Safety Logic (Sequencing Needs)

What sequence must be enforced? Is it a simple two-valve isolation or a complex multi-step process?

- Simple Key Exchange: A basic mechanical key interlock for valves where the key from one interlock releases the key to another.

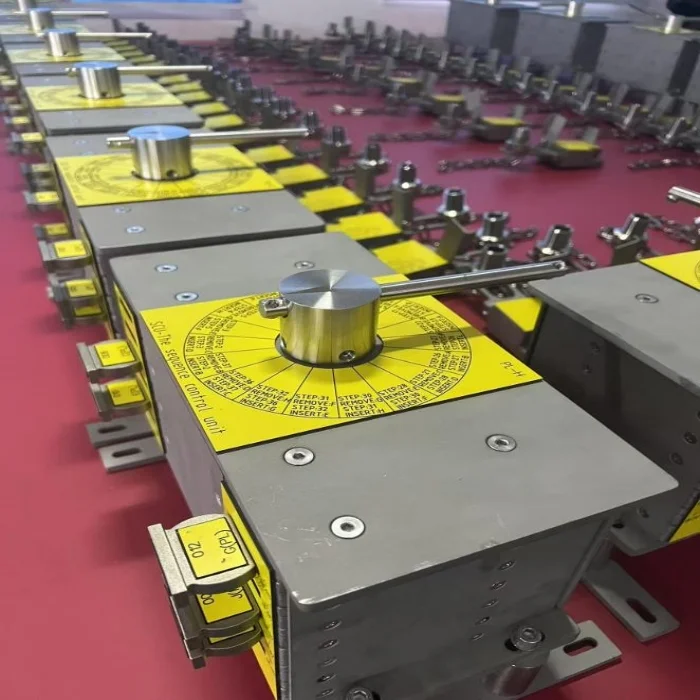

- Sequential Valve Interlock System: For complex processes involving multiple valves and equipment. This requires a mechanical interlock for valve safety management that uses a Sequential Control Unit (SCU). Nudango's SCU acts as a central controller, releasing keys only in the precise, safe order.

Figure 3: The heart of complex safety sequencing: Nudango's SCU enables a fully sequential valve interlock system, preventing procedural errors.

Step 4: Consider Customization and Integration

Off-the-shelf solutions don't always fit. Valve handwheel sizes, space constraints, and existing infrastructure vary.

Shanghai Nodango Safety Equipment Co., Ltd. excels in providing customized valve interlock solutions. Whether you need a bespoke pipeline valve interlock safety device or a modified gear box valve interlock, their engineering team can adapt designs to your specific valves and layout, ensuring a perfect fit and optimal safety.

Step 5: Verify Compliance and Quality

Always choose a supplier with proven quality and international recognition. Nudango operates under a stringent GB/T19001-2015 idt ISO9001:2016 quality management system. Their commitment is further validated by certifications for Environmental and Occupational Health & Safety Management systems. Furthermore, their products often carry the CE mark, facilitating their use in projects across Europe and other regions that recognize this standard.

Nudango's products, including its valve interlock systems, are designed and manufactured to meet rigorous international standards like CE.

Why Partner with Nudango?

With over years of specialization, Nudango is more than just a manufacturer. They offer a full spectrum of services—safety planning, consulting, design, manufacturing, and after-sales support. Their products, exported worldwide to countries like Germany, Saudi Arabia, Brazil, and India, are trusted in the most demanding sectors.

Their modern production facility in Shanghai ensures high-quality manufacturing and timely delivery.

Nudango's advanced production workshop, where precision and quality control define every mechanical valve interlock system produced.

Conclusion

Selecting the right valve interlock is a systematic process that balances technical requirements, environmental challenges, and safety logic. By following this guide and partnering with an experienced provider like Shanghai Nodango Safety Equipment Co., Ltd. (Nudango), you can implement a robust mechanical interlock for valve safety management that protects your assets, your personnel, and your bottom line.

For a detailed consultation or to explore customized valve interlock solutions for your specific needs, contact Nudango today.

Contact Nudango:

Phone: +86 13052019523 | WhatsApp: +86 13816485040

Email: globalnudango@shndg.cn

Website: https://www.nudango.com/

Address: No.124, Block C, No.1118 Guchen Road, Baoshan District, Shanghai, P.R.C.