How to Choose the Perfect Valve Interlock: A Step-by-Step Guide for Safety Managers

Selecting the correct Valve Interlock system is a critical decision for any industrial facility. With the wrong choice, you risk operational inefficiencies, safety hazards, and non-compliance. This guide, brought to you by Shanghai Nodango Safety Equipment Co., Ltd. (Nudango), will walk you through the key factors to consider, ensuring you implement a Mechanical valve interlock system that enhances safety and streamlines your processes.

Why Valve Interlocks Are Non-Negotiable in Modern Industry

Recent industry reports highlight a continued focus on process safety management (PSM) in sectors like oil & gas and petrochemicals. A Safety valve interlocking device is no longer just an accessory; it's a fundamental component of a robust safety instrumented system (SIS), preventing human error during complex valve sequencing in isolation, purging, or startup/shutdown procedures.

Step 1: Identify Your Valve Type and Motion

The type of valve dictates the interlock mechanism. This is the most fundamental selection criterion.

- For Ball Valves, Plug Valves (90° operation): A Quarter-turn valve interlock is designed specifically for this motion. It ensures the valve is either fully open or fully closed before releasing the key.

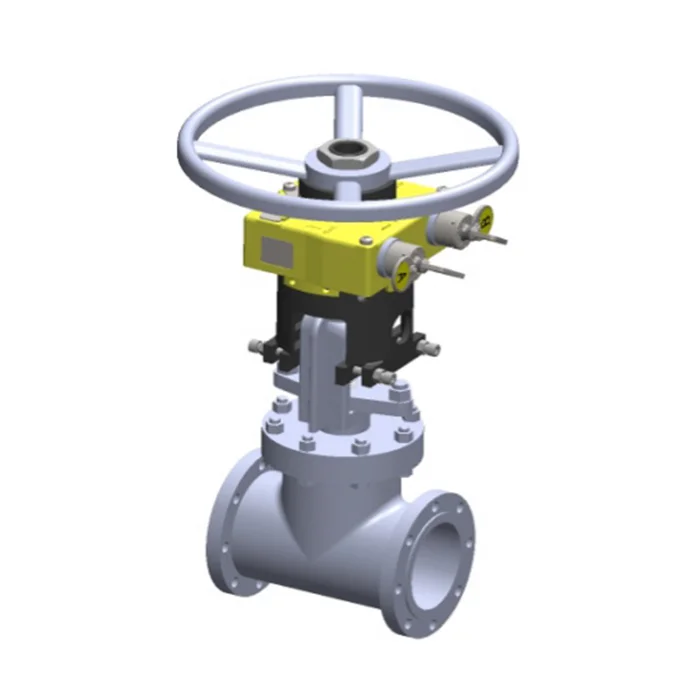

- For Gate, Globe, Rising Stem Valves (Multi-turn operation): You need a Multi-turn valve interlock. These devices, like Nudango's VDS/VDL models, control the multiple rotations required to operate these valves safely.

- For Valves with Actuators or Gearboxes: Specialized solutions exist. A Drive Valve Interlock or Gear box valve interlock secures the drive mechanism itself, providing an added layer of protection for automated or hard-to-turn valves.

Nudango's Multi-turn valve interlock (model VDS / VDL) is engineered for precise control of gate and globe valves.

Step 2: Assess Your Operational Environment

The operating conditions are crucial for material selection and durability.

- Standard Industrial Environments: Powder-coated carbon steel offers a cost-effective and robust solution.

- Corrosive, Coastal, or Chemical-Exposed Areas: A Stainless steel valve interlock or specifically a Corrosion-resistant valve interlock is mandatory. This prevents failure due to rust and chemical attack.

- Hazardous Areas with Flammable Atmospheres: In the oil and gas industry or certain petrochemical zones, an Explosion-proof valve interlock certified for the specific zone (like ATEX or IECEx) is required to prevent ignition.

- General Harsh environment valve interlock requirements: Look for features like excellent sealing (moisture-proof, dust-proof) which are hallmarks of Nudango products, proven in global projects from Saudi Arabia to Germany.

Step 3: Define Your Safety Logic (Key Sequencing)

What is the safety procedure you need to enforce? This determines the system complexity.

- Simple Isolation (One Valve): A basic Key-operated valve interlock or Mechanical key interlock for valves works perfectly. The key is trapped until the valve reaches the correct position.

- Complex Sequential Procedures (Multiple Valves): This is where a Sequential valve interlock system shines. It forces operators to follow a pre-defined sequence (e.g., close Valve A before opening Valve B) by controlling the transfer of a single key or multiple keys through a device like Nudango's SCU (Sequential Control Unit). This is vital for safe pipeline isolation and system bypass management.

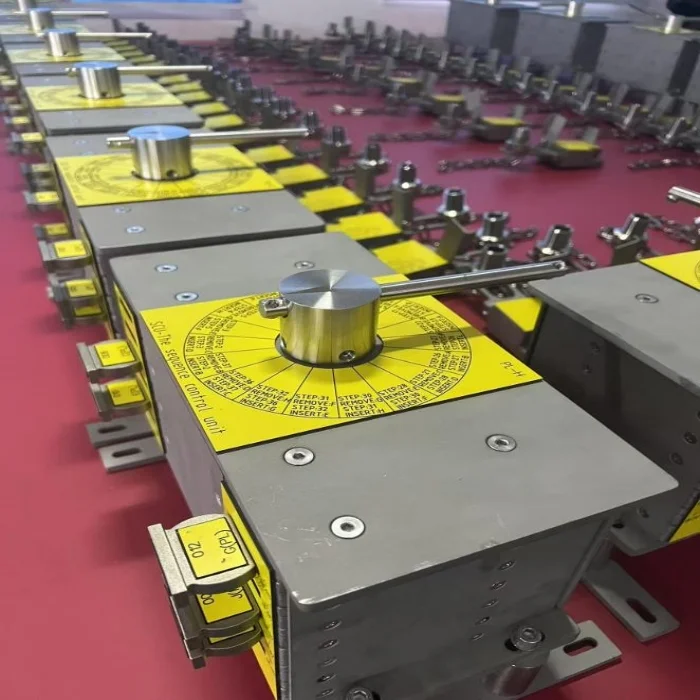

The Nudango SCU (Sequential Control Unit) is the brain of a complex Sequential valve interlock system, enforcing safe operating procedures.

Step 4: Consider Integration and Customization

Off-the-shelf solutions don't always fit. Valve handwheel sizes, space constraints, and unique procedural needs may require tailored designs.

- Standard Solutions: Cover most common valve types and applications.

- Customized valve interlock solutions: Reputable manufacturers like Nudango offer engineering support to design interlocks for non-standard valves, tight spaces, or integration with existing lockout/tagout (LOTO) systems. This ensures the Pipeline valve interlock safety device fits perfectly into your specific Industrial valve safety interlock strategy.

Step 5: Verify Manufacturer Credentials and Support

Your interlock is a safety-critical device. The manufacturer's pedigree matters.

- Certifications: Always choose a manufacturer with internationally recognized quality and safety management certifications. Shanghai Nodango Safety Equipment Co., Ltd. operates under a GB/T19001-2015 idt ISO9001:2016 quality management system and holds certificates for Environmental and Occupational Health & Safety Management Systems, alongside CE marking for relevant products.

- Technical Expertise & After-Sales: Can they provide design consultation? Do they have a track record in your industry (e.g., Valve interlock for oil and gas industry)? Nudango's collaboration with research institutions and extensive export experience to regions like Vietnam, India, Brazil, and Algeria demonstrates their capability to handle diverse, demanding projects.

- Global Support: For international clients, ensure the manufacturer can provide documentation, spare parts, and support globally. You can reach Nudango at +8613052019523, WhatsApp: +8613816485040, or globalnudango@shndg.cn.

The Nudango Advantage in Valve Safety Management

As a professional provider of Mechanical interlock for valve safety management solutions, Nudango doesn't just sell products; we deliver engineered safety. Our product range, from simple Rotary motion valve interlock (Model VJ) to complex sequential systems, is built for reliability in the toughest conditions. We encourage you to visit our website at https://www.nudango.com/ to explore our full portfolio and see how our Customized valve interlock solutions can be integrated into your safety plan.

Precision manufacturing in Nudango's production workshop ensures the highest quality for every valve interlock.

Conclusion: Selecting the right Valve Interlock involves a careful analysis of valve type, environment, safety logic, and supplier capability. By following this guide, safety engineers and plant managers can make an informed decision that enhances operational integrity and protects both personnel and assets. Investing in a high-quality, well-suited Mechanical valve interlock system from a trusted partner like Nudango is an investment in preventable safety and uninterrupted productivity.