How to Select the Right Valve Interlock System for Your Industrial Safety Needs

In today's high-stakes industrial environments, from sprawling petrochemical complexes to offshore platforms, ensuring operational safety is not just a regulatory requirement—it's a fundamental pillar of business continuity and personnel protection. At the heart of many process safety strategies lies the valve interlock, a critical device designed to enforce safe operating sequences and prevent human error. With a myriad of options available, selecting the appropriate system can be a daunting task. This guide, brought to you by Shanghai Nodango Safety Equipment Co., Ltd. (Nudango), will walk you through the key considerations to help you choose the perfect mechanical valve interlock system for your application.

Understanding Valve Interlock Fundamentals

A valve interlock is essentially a mechanical or mechatronic device that controls access to valves, ensuring they are operated in a predetermined, safe sequence. By using a physical key exchange logic, it prevents dangerous situations like simultaneously opening and closing interconnected valves, bypassing safety systems, or starting a pump before a valve is open. The core principle is simple: one key is trapped until the correct valve position is achieved, forcing operators to follow the procedure.

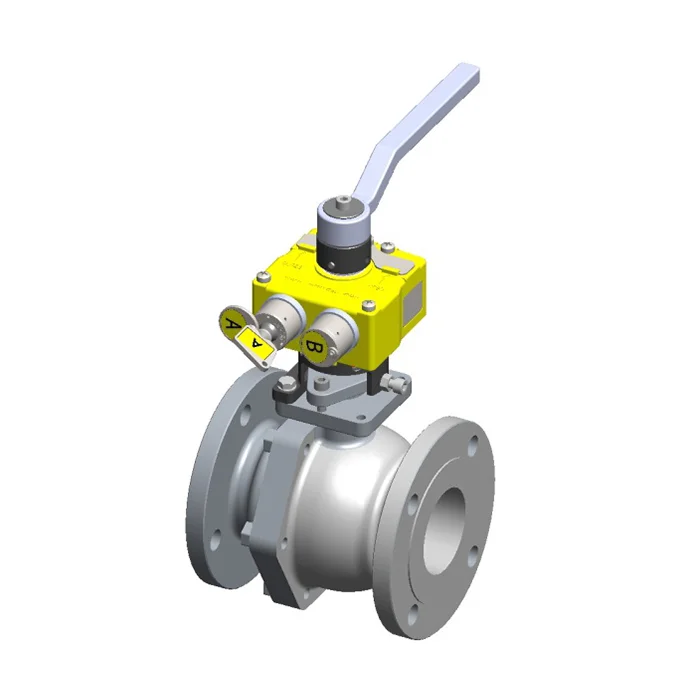

Nudango's VJ model is a classic example of a robust rotary motion valve interlock, designed for quarter-turn valves like ball and plug valves.

Step 1: Identify Your Valve Type and Motion

This is the most critical first step. The physical motion of your valve dictates the interlock type.

- Quarter-Turn Valve Interlock: Designed for valves that require a 90-degree rotation to open or close, such as ball, plug, and butterfly valves. These are often compact and directly mounted on the valve stem. Nudango offers specialized solutions for these applications.

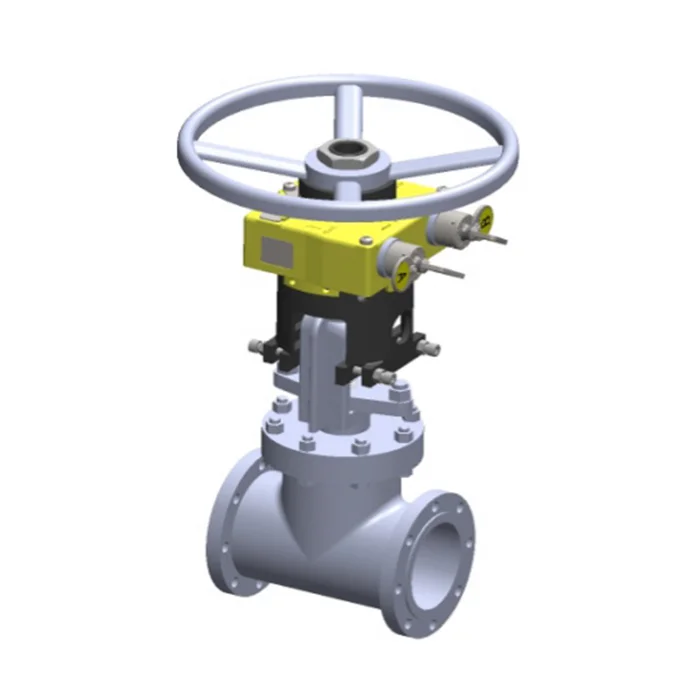

- Multi-Turn Valve Interlock: Used for valves like gate, globe, and diaphragm valves that require multiple rotations (e.g., 5-10 turns) of a handwheel. These interlocks, such as Nudango's VDS/VDL models, are designed to engage with the handwheel or stem and monitor the complete rotational travel.

- Drive Valve Interlock & Gear Box Valve Interlock: For valves operated by actuators, gearboxes, or chain wheels. These systems lock the drive mechanism itself, ensuring safety at the point of operation. They are essential for large, hard-to-reach valves common in the oil and gas industry.

Step 2: Assess Your Operational Environment

The operating conditions will determine the required material and protection features of the industrial valve safety interlock.

- Corrosive Atmospheres: In chemical plants or marine environments, a stainless steel valve interlock or one with special coatings is mandatory to prevent failure due to corrosion.

- Explosive Areas: For zones with flammable gases or dust, an explosion-proof valve interlock certified for the specific zone (like ATEX or IECEx) is non-negotiable. While mechanical interlocks are inherently safe, their construction must prevent sparking.

- Harsh Environment Valve Interlock: Consider factors like extreme temperatures, high pressure washdowns, UV exposure, and abrasive dust. Look for devices with excellent moisture-proof, mildew-proof, rust-proof, and dust-proof properties, a hallmark of Nudango products built for longevity.

Step 3: Define Your Safety Logic (Sequential Needs)

What specific hazardous scenario are you trying to prevent? This defines the logic of your interlock system.

- Simple Key Exchange: A basic two-valve system where the key from Valve A releases only after it's in the correct position, and that key is then used to operate Valve B.

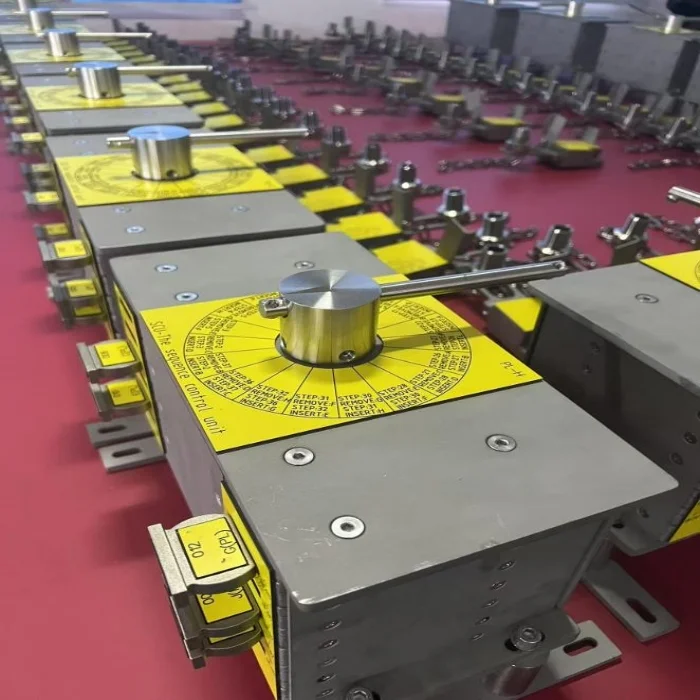

- Sequential Valve Interlock System: For complex processes involving multiple valves and equipment. This requires a mechanical key interlock for valves arranged in a sophisticated logic sequence, often managed by a central Sequential Control Unit (SCU). Nudango's SCU is a master controller that can manage intricate sequences across an entire plant section.

- Safety Valve Interlocking Device: Specifically designed to lock critical safety valves (like pressure relief valves) in the correct position, ensuring they are never inadvertently isolated or tampered with.

Step 4: Consider Operational and Maintenance Factors

Usability impacts long-term compliance and effectiveness.

- Key-Operated Valve Interlock: The most common and reliable type. Ensure keys are durable, uniquely coded to prevent cross-use, and manageable in number for operators.

- Customization: Standard solutions may not fit every valve or layout. A provider capable of offering customized valve interlock solutions is invaluable. Nudango's engineering team specializes in adapting designs to fit unique valve configurations, legacy equipment, and spatial constraints.

- Ease of Installation & Maintenance: The system should be installable without major valve modification. Look for designs that allow for easy inspection and minimal maintenance even in continuous operation environments.

Step 5: Verify Compliance and Manufacturer Credentials

Your interlock system is a safety-critical component. Partner with a manufacturer that demonstrates a commitment to quality and safety standards.

Shanghai Nodango Safety Equipment Co., Ltd. stands out in this regard. The company operates under a rigorous GB/T19001-2015 idt ISO9001:2016 quality management system, ensuring consistent product excellence. Furthermore, their commitment to holistic safety management is validated by their certifications for Environmental and Occupational Health & Safety systems. Their products also carry the CE mark, facilitating their use in international projects.

Nudango's ISO 9001 certification is a testament to their systematic approach to quality in designing and manufacturing valve interlock systems.

Why Choose Nudango as Your Valve Interlock Partner?

With over years of dedicated focus on safety engineering, Nudango has positioned itself as a leader in mechanical interlock for valve safety management. Their expertise spans the entire lifecycle—from initial safety planning and consulting to design, manufacturing, and after-sales support.

Their pipeline valve interlock safety device and petrochemical valve interlock system are trusted in some of the world's most demanding facilities across Vietnam, India, Saudi Arabia, Brazil, Germany, and beyond. Their in-house R&D, backed by collaborations with universities, fuels continuous innovation, resulting in numerous patented technologies.

Selecting the right valve interlock is a strategic decision that reduces risk, ensures compliance, and protects your most valuable assets: your people and your plant. By methodically evaluating your valve type, environment, safety logic, and operational needs, you can implement a system that provides reliable, long-term safety.

For a detailed consultation on customized valve interlock solutions for your specific application in the power, shipbuilding, oil and gas, or any heavy industry, contact the experts at Nudango.

Shanghai Nodango Safety Equipment Co., Ltd. (Nudango)

Phone: +86 13052019523 | WhatsApp: +86 13816485040

Email: globalnudango@shndg.cn

Website: https://www.nudango.com/

Address: No.124, Block C, No.1118 Guchen Road, Baoshan District, Shanghai, P.R.C.