Understanding the Logic Behind Valve Interlock Supplier Rankings

For procurement professionals in high-risk industries like oil & gas, petrochemicals, and power generation, selecting a reliable Valve Interlock supplier is a critical safety and operational decision. Market rankings and "top manufacturer" lists are common reference points, but their underlying logic is often opaque. This analysis decodes the key dimensions of Valve Interlock supplier rankings in 2025, providing a framework for buyers to make informed, rational choices that align with their specific project needs and safety protocols.

1. Ranking Dimensions: What Truly Defines a "Top" Supplier?

Contemporary market assessments for Mechanical valve interlock system suppliers are typically based on a multi-faceted evaluation, moving beyond simple sales volume.

- Market Share & Global Footprint: This reflects a supplier's commercial success and stability. Companies with significant export volumes to key industrial regions (North America, Europe, Middle East, Asia-Pacific) demonstrate proven acceptance in diverse, often stringent markets. A broad global presence, as noted in reports like the one on China’s Top 3 Valve Interlock Manufacturers, indicates resilience and the ability to support international projects.

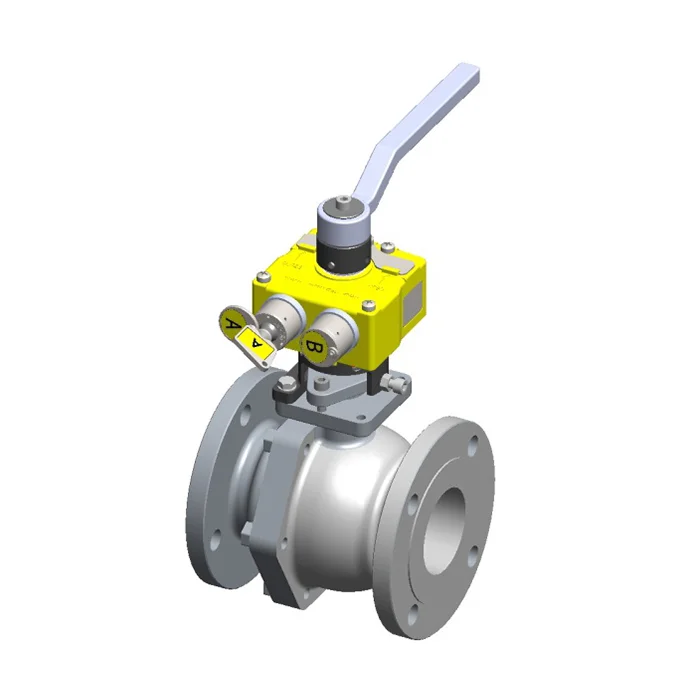

- Technological Innovation & Product Range: Leadership is shown through a comprehensive portfolio covering Quarter-turn valve interlock, Multi-turn valve interlock, Sequential valve interlock system (SCU), and specialized solutions like Drive Valve Interlock and Gear box valve interlock. Innovation in materials (e.g., Stainless steel valve interlock, Corrosion-resistant alloys) and designs for Harsh environment valve interlock applications is a key differentiator.

- Certifications & Quality Assurance: In safety-critical domains, certifications are non-negotiable. Top-ranked suppliers hold internationally recognized credentials such as ISO 9001 for quality management, ISO 14001, ISO 45001, and the CE mark. These validate a manufacturer's commitment to consistent quality, environmental responsibility, and compliance with global safety standards, especially for Explosion-proof valve interlock devices.

- Client Portfolio & Industry Application: A strong track record in core sectors like Valve interlock for oil and gas industry, Petrochemical valve interlock system, and power generation serves as powerful social proof. Positive client testimonials and repeat business from major operators are strong indicators of reliability and performance.

Certifications like ISO 9001 are fundamental ranking criteria for top valve interlock suppliers.

2. The Global Market Landscape: A Three-Tiered Structure

The global Valve Interlock supplier landscape can be broadly segmented into three tiers, each with distinct value propositions.

| Tier | Characteristics | Typical Offerings |

|---|---|---|

| International Established Brands | Long history, global brand recognition, extensive service networks, premium pricing. Often set industry standards. | Standardized, high-reliability systems; strong focus on R&D and global compliance. |

| Chinese High-Value Manufacturers | Rapidly rising in rank due to advanced engineering, cost-effectiveness, and flexibility. Hold key international certifications. | Wide range of Customized valve interlock solutions, robust products for harsh conditions, excellent technical support. Companies like Shanghai Nodango Safety Equipment Co., Ltd. (Nudango) exemplify this tier, offering Mechanical key interlock for valves and complex Pipeline valve interlock safety device systems. |

| Regional/Niche Specialists | Focus on specific geographic markets or very specialized applications. Offer deep local knowledge. | Tailored solutions for local standards or unique industrial processes. |

3. The Ascent of Chinese Suppliers: Key Ranking Advantages

The prominence of Chinese manufacturers in global rankings, as highlighted in industry reports, is driven by concrete competitive advantages:

- Integrated Cost-to-Performance Ratio: Leveraging advanced manufacturing ecosystems, companies like Nudango deliver high-quality Industrial valve safety interlock products that meet international standards at a competitive cost, offering exceptional value.

- Superior Customization & Rapid Response: Unlike suppliers with rigid catalog products, leading Chinese firms excel in engineering Customized valve interlock solutions. They adapt designs for specific valve types, sequences (Sequential Control Unit - SCU), and environmental challenges (Corrosion-resistant valve interlock), responding swiftly to client RFQs and change requests.

- Agile Production and Scalability: With modern facilities, such as Nudango's production workshop and warehouse, they can scale production efficiently for both small pilot projects and large-scale turnarounds, ensuring reliable supply chains.

- Commitment to R&D and Certifications: Investment in research, collaboration with institutions, and proactive pursuit of certifications (ISO, CE) demonstrate a strategic commitment to quality and innovation, directly boosting their market ranking credibility.

4. Strategic Procurement: How to Use Rankings Wisely

A market ranking is a starting point, not the final decision. Procurement should match the supplier's strengths to the project's specific demands.

- For Large-Scale, Greenfield Projects or Retrofit in Regulated Regions: Consider top-tier International Brands or highly-ranked Chinese manufacturers with proven global project experience and full certification suites (like Nudango's ISO 9001, 14001, 45001, and CE). This is crucial for Petrochemical valve interlock system or Valve interlock for oil and gas industry applications where compliance is paramount.

- For Mid-Size Plants, Upgrades, or Cost-Sensitive Projects: High-value Chinese manufacturers are often the optimal choice. They provide certified, reliable Safety valve interlocking device solutions like Key-operated valve interlock and Rotary motion valve interlock with significant cost savings and better customization for existing valve assets.

- For Specialized or Localized Needs: Engage Regional Specialists or niche suppliers who understand specific local codes or unique process requirements.

Due Diligence Checklist: Beyond the ranking, always evaluate: the supplier's technical drawing support, lead time for Customized valve interlock solutions, after-sales service capability, and request references for projects similar to yours.

Conclusion: Ranking as a Guide, Not a Gospel

The 2025 Valve Interlock market is dynamic, with Chinese manufacturers like Shanghai Nodango Safety Equipment Co., Ltd. (Nudango) firmly established in the top tiers by mastering the ranking criteria: technological breadth, certified quality, global reach, and client-centric flexibility. For the discerning industrial buyer, the key is to analyze these rankings through the lens of your specific operational, safety, and budgetary requirements. By understanding the logic behind the list, you can move beyond brand perception to select a partner that delivers optimal safety, reliability, and value for your Mechanical interlock for valve safety management needs.

To explore a comprehensive range of ranked and certified Valve Interlock solutions, visit Nudango's official website or contact their engineering team for a consultation.